“In the middle of the difficulty, lies an opportunity.”

Albert Einstein

India has proved this quote true. It has emerged to become the second-largest manufacturer for personal protective equipment (PPE) kits. This happened within a short period of two months after the pandemic arose in India in March 2020. PPE kits mainly include masks (surgical and N-95), gloves (surgical and examination), coveralls and gowns, head cover, goggles, face-shields, and shoe cover. India has efficiently begun to manufacture these PPE kits due to the widespread Coronavirus pandemic.

Challenges faced for manufacturing

Currently, China is the world leader in both the manufacture and export of PPE kits. India imported lakhs of PPE kits from China but the kits received were faulty and of low quality. The US and the Asia Pacific have a combined market share of 61 percent. The US has 33 percent and Asia Pacific Region has a 28 percent share of PPE kits. On the other hand, Europe has a share of 22 percent.

So, how did it happen for India? With a nation with having a population of 1.3 million, it was very difficult to depend on the imports. Dr. Sanjiv Relhan, the Chairman of Preventive Wear Manufacturer Association of India stressed upon the one significant fact. There were 100+ firms in India making the gowns, bodysuits, and other gears like masks, gloves to fight coronavirus. But the problem came into highlight when no one was making the sealed bodysuits. Such bodysuits use tape and worn by the doctors to protect themselves from this harmful virus while treating the patients. The issue of shortage of unique tape sealing machines was also creating havoc. There was a lack of standardization in this and cheap kits from China was creating more dilemma.

Implementation of a powerful solution

The government came into action in early January 2020. Under the leadership of Smriti Irani, the Textile Ministry team has been taking many crucial steps. It is ensuring that only certified players are eligible to make the kits. These players include Nair Matrix Clothing, Arvind Ltd, Rich Global Exports Pvt Ltd, and so on. These firms across the entire supply chain are successfully supplying PPE kits to the government. Within a month, 14 manufacturers cleared the technical testing and the number of manufacturers grew to 52 in next month. This continued to grow further. Some manufactures are now using ultrasonic sealing waves. This helps in sealing the edges of the bodysuits just like using an iron to stick the stickers on the t-shirts.

Moreover, India has started to use the alternative of Nitrile power-filled gloves by replacing them with lactic gloves. This is because lactic gloves are less costly. The fabric of the bodysuit used is non-woven which helps to optimize the costs. But the variety of lightweight woven fabric is also used by many manufacturers. These PPE kits ensure to cover the overall body of the frontline workers with the provision of a zip-up facility. Also, the Textile Committee is sincerely doing the work of establishing laboratories for the testing of textiles and textile machinery. They provide the tests for inspection and examination considering the factor for the quality of textile products and textile machinery.

Growth in productions of PPE kits

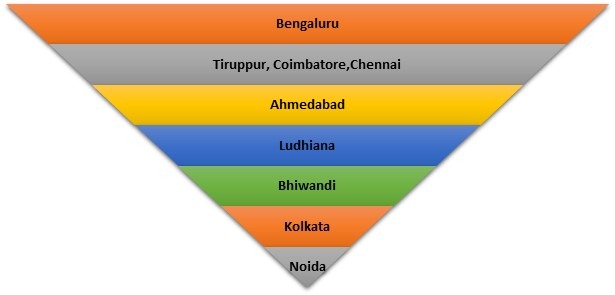

When compared to March 30, India produced 8,000 PPE every day. Stating the recent scenario of May 18, India produced 4.5 lakh PPEs per day. Arvind manufacturer produces 15,000 PPE kits per day and serves through their plants situated in Bengaluru, Ahmedabad, and Ranchi. Their executive director, “Kulin Lalabhai” also applauded the government of India that works with the textile industry from scratch. For Shahi Exports, only 5 of its 58 plants are into service for manufacturing these kits. Out of 1.2 lakhs, only 750 employees are deployed on the plants. The company now successfully makes 20,000 bodysuits per day. It has supplied over 9 lakhs kits to “Hindustan Lifecare Limited (HLL)” in Kerala, the Central government’s agency in charge of medical procurement.

There is immense growth in this arena which is highly commendable. In just 60 days, there was a 56-fold growth. It is estimated to be 7,000 crore industry in the future. India has so far an inventory of 15.96 lakh PPE kits. Another 2.22 crore kits are in the process of manufacturing for future requirements. The interesting fact here is that more than 600 companies in India are now certified to produce PPEs. The global market worth is certainly to be $92.5 billion by 2025.

Future scope and improvements in PPE kits

There is a high demand for PPE kits for frontline workers due to increasing cases of Coronavirus in India. Thereby, these are banned to give in export too. In a recent webinar, the Apparel Export Promotion Council (AEPC) has emphasized for the lifting of the ban on export. This is possible once the local manufacturers can meet the Indian demand well.

Also, the government is boosting this business on another level by helping the Micro, Small, and Medium Enterprises (MSMEs). The World Bank and the Asian Development Bank are providing trade finance programs to MSMEs. Also, they have decided to tie-up with technological companies. It will set up the analytics to maintain optimum stock levels, limit wastage, and avoid stock-outs of the kits. Some Government institutes like the Defence Research and Development Organisation (DRDO) are finding innovative methods for testing the kit’s materials. With these practices into place, it will improve the quantitative and qualitative requirements of PPE kits. This good news will spread positivity within the frontline warriors. They are able to gain more confidence in their work and are giving their best to combat this pandemic.